График работы в Карантин

Returning talk

Returning talk

Leave the room, and we will call you back

Alta-Step is a 100% waterproof vinyl SPC laminate.

Stone Plastic Composite (SPC) means “stone-plastic composite.” The main layer of the laminate panel consists of a composition of calcium carbonate and vinyl, which makes this type of flooring highly resistant to abrasion and 100% waterproof.

These qualities distinguish SPC laminate from simple laminate with an HDF base and put it on a par with high-quality ceramic tiles in terms of performance.

34 класс нагрузки

43 класс износостойкости

Водостойкий

Экологически безопасный

Замковая система монтажа

Совместим с «теплым полом»

34 класс нагрузки

43 класс износостойкости

Водостойкий

Экологически безопасный

Замковая система монтажа

Совместим с «теплым полом»

Specifications

| Panel size: | 1218х180х5мм |

| Protective layer: | 0,3 мм |

| Packaging: | 12 pcs/2.631 m2 |

1. PREPARATION FOR INSTALLATION

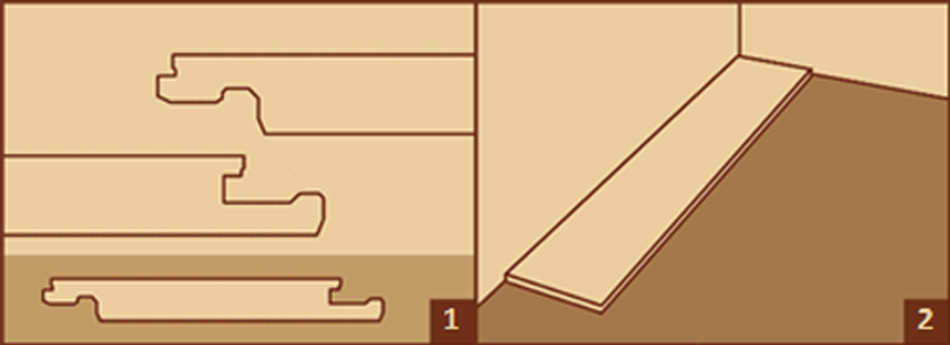

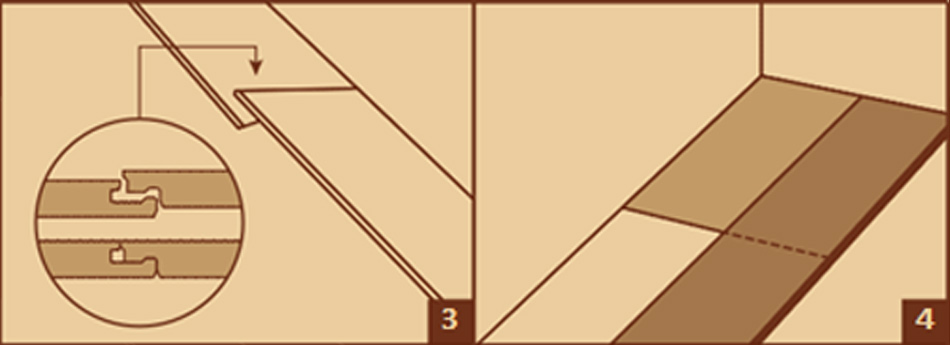

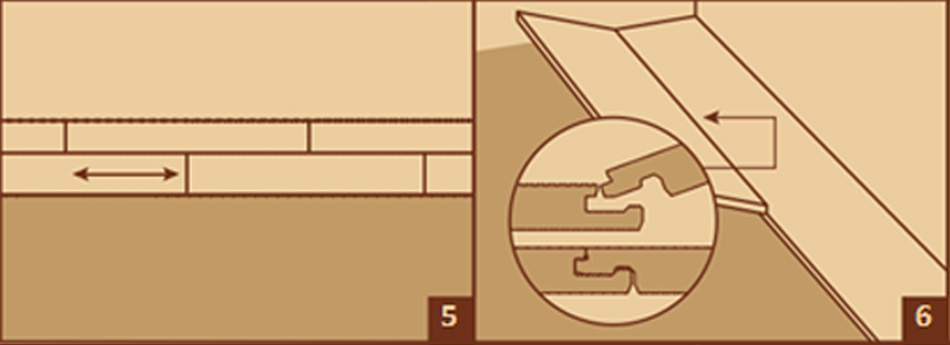

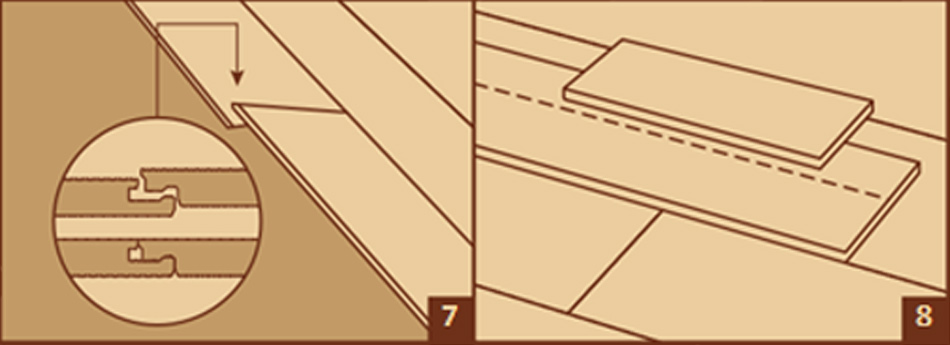

1.1. The floor must be clean, dry, level, and free of sharp unevenness. 1.2. Before laying vinyl laminate, it is recommended to keep it in a horizontal position at room temperature for 24 hours. 2. General provisions 2.1. Vinyl laminate with a “Click” locking system does not require gluing or other methods of fixing to the surface. 2.2. The “Click” locking system allows panels to be joined in two different ways: tongue into groove or groove into tongue. (Fig. 1) 2.3. Vinyl laminate can be laid starting from any point in the room and in any direction: from left to right or from right to left, taking into account the sequence of the end lock connections. 3. Laying VINYL laminate 3.1. Begin laying the material from any corner of the room. 3.2. Lay the first row in a straight line. Align the end lock of each panel with the end lock of the previously installed panel without shifting them relative to each other and lock the panel locks. To fasten the end locks, it is sufficient to lightly touch the two sides of the end lock. For a secure connection of the locks, it is advisable to use a rubber mallet.

3.3. When laying the second row, insert the panel to be laid with the long side lock at an angle of approximately 25° to the corresponding lock of the panel already laid, then lock the lock with slight pressure towards the laid panel and simultaneously lower it onto the floor. 3.4.

3.5. To lay the last row, it is usually necessary to cut the panel. 4. Laying VINYL laminate 5. Vinyl laminate can be laid on any type of heated floor, but the base must be solid and hard. 6. Use. 7. Vinyl laminate manufactured to the highest quality standards will give you positive emotions for many years. 8. Care for vinyl flooring. 9. The flooring can be washed with any cleaning agents, including those containing alcohol and alkalis. Any dirt, even ink and marker stains, can be easily removed from it.

10. BUT! It is not recommended to use powdered cleaning agents to avoid a matte finish on the panel.

сравнительные характеристики

| Какое покрытие для пола лучше | ||||||

|---|---|---|---|---|---|---|

| Линолеум | Ковролин | Плитка | Ламинат | Паркет | Виниловый ламинат | |

| Прочное | Да | Да | Not | Not | Да | Да |

| Бесшумное | Да | Да | Not | Not | Not | Да |

| Водостойкое | Да | Not | Да | Not | Not | Да |

| Нескользкое | Not | Да | Not | Да | Да | Да |

| Пожаробезопасное | Not | Not | Да | Да | Not | Да |

| Простое в уходе | Да | Not | Да | Да | Not | Да |

| Простое в монтаже | Да | Да | Not | Да | Not | Да |

| Долговечное | Not | Not | Да | Not | Да | Да |

100% waterproof and non-slip

100% waterproof and non-slip Vinyl laminate is completely waterproof. PVC material is impervious to moisture and does not absorb water. Thanks to the unique panel joint system, moisture does not penetrate between the segments, preventing water from getting under the laminate and causing further damage. This system allows the laminate to be installed even in bathrooms.

The top layer of the laminate is made of polyurethane, which protects the pattern from sunlight. Usually, wood-effect laminate consists of a pattern on a decorative layer and light embossing. We went further: we created a texture that is difficult to distinguish from wood even to the touch.

In addition, the textured top layer not only imitates the surface of wood, but also reduces the slip coefficient, making the floor surface non-slip and safe for both adults and children.

Speaking of children, if your little one paints the floor with paints or markers, don't worry. Vinyl siding is designed for children's creativity. It is easy to clean.

Wear resistance class 34. Warranty period - 20 years.

The vinyl laminate has a wear resistance class of 34, which is considered the new generation standard. This class of flooring was developed specifically for high-traffic areas (gyms, train stations, airports).

This choice for your home will allow you to forget about floor repairs for the next few decades. You can cover the floor in a store or restaurant, and the unique oak patterns will emphasize the high taste of the owner of the establishment. The material is safe, not only because it is non-slip, but also because it does not emit harmful substances and is fire resistant. Vinyl is used on floors in kindergartens, hospitals, and swimming pools. It is used to make drinking bottles, children's toys, and syringes.

One of the advantages of Alta Step panels is sound insulation — an important factor when choosing flooring. The advantage of our laminate is the sound-absorbing underlayment built into the panels. This is a two-in-one solution, as we have already reduced your costs for additional sound-absorbing underlayment.

Patented locking system

The laminate material uses a modern modification of polyvinyl chloride film, which is more durable and does not pose a threat to human health. This material is environmentally friendly.

The technological advantage of Alta Step vinyl laminate is its compatibility with underfloor heating systems.

Thanks to the combined underlay, which is pre-installed on the panels, we have simplified the installation of the laminate. There is no longer any need to make an additional subfloor for the panels.

Considering that glue is time-consuming and inconvenient to work with, we immediately abandoned it and replaced it with a locking system: our laminate can be easily installed by yourself. Just follow the instructions.

And we have already taken care of durability. SPC laminate will last more than 20 years and will look like new. It can withstand temperatures from -30°C to 80°C.

Заказать ламинат